the spigot aluminum tubular folding truss system represents a significant advancement in temporary structure technology. Its lightweight design, rapid assembly, and inherent strength make it a highly versatile and efficient solution across a broad range of applications. While some limitations exist, ongoing advancements in materials and design are continuously improving its performance and expanding its potential. The system’s enduring popularity underscores its crucial role in shaping modern temporary structures and supporting a wide spectrum of industries.

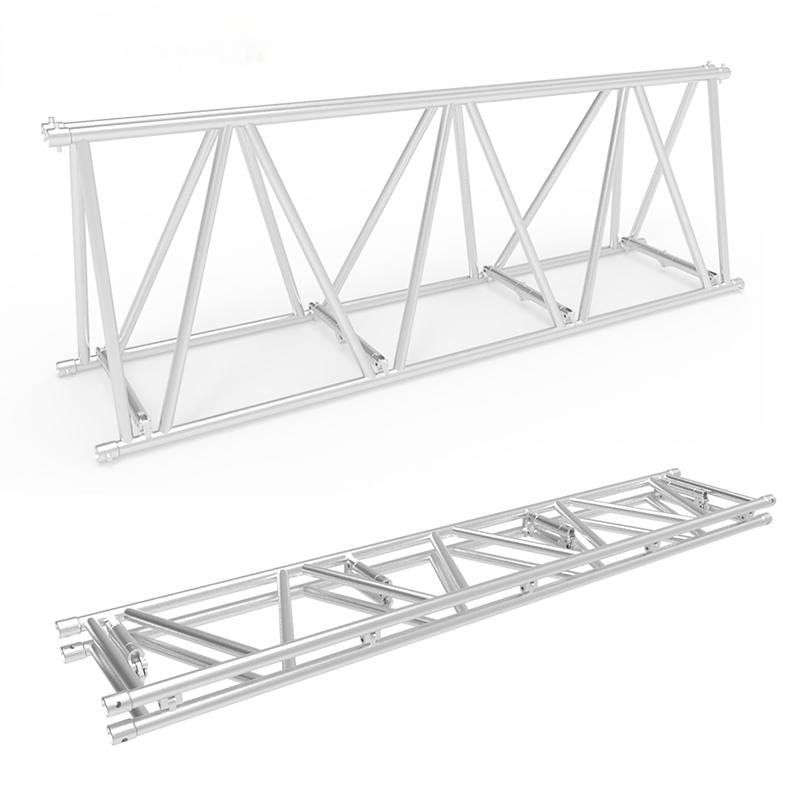

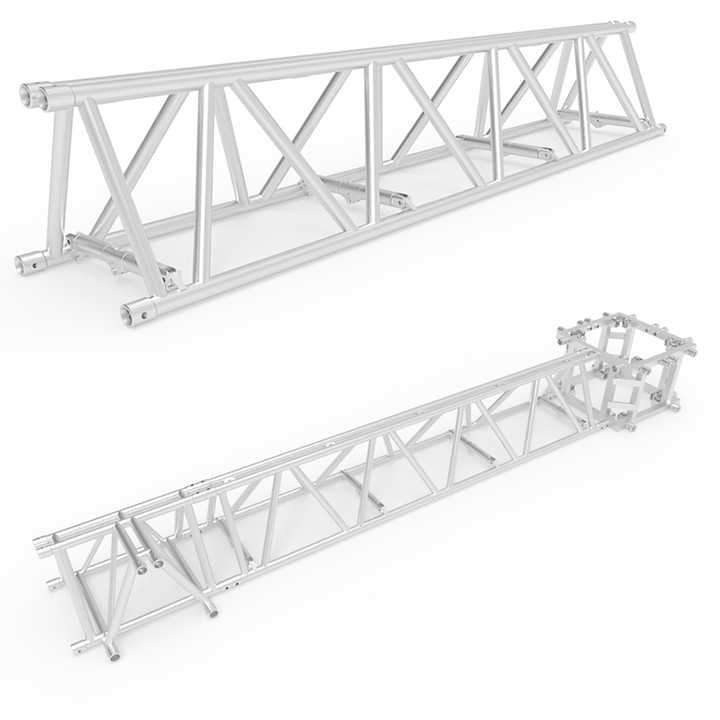

The fundamental design of a spigot aluminum tubular folding truss hinges on its namesake components: spigots. These are precisely engineered conical connectors that facilitate the quick and secure joining of individual aluminum tubes, forming a robust lattice structure. Unlike traditional bolted or pinned systems, the spigot design relies on a friction-fit mechanism, eliminating the need for extensive fastening hardware and significantly reducing assembly time. The tubes themselves are typically made from high-strength, lightweight aluminum alloy, often 6061-T6 or similar, chosen for its excellent strength-to-weight ratio, corrosion resistance, and ease of machinability. The precise dimensions and wall thickness of these tubes are critical to the overall structural integrity of the truss, ensuring optimal load-bearing capacity and preventing fatigue failure under stress. The selection of alloy and tube dimensions is dictated by the intended load capacity and span of the truss.

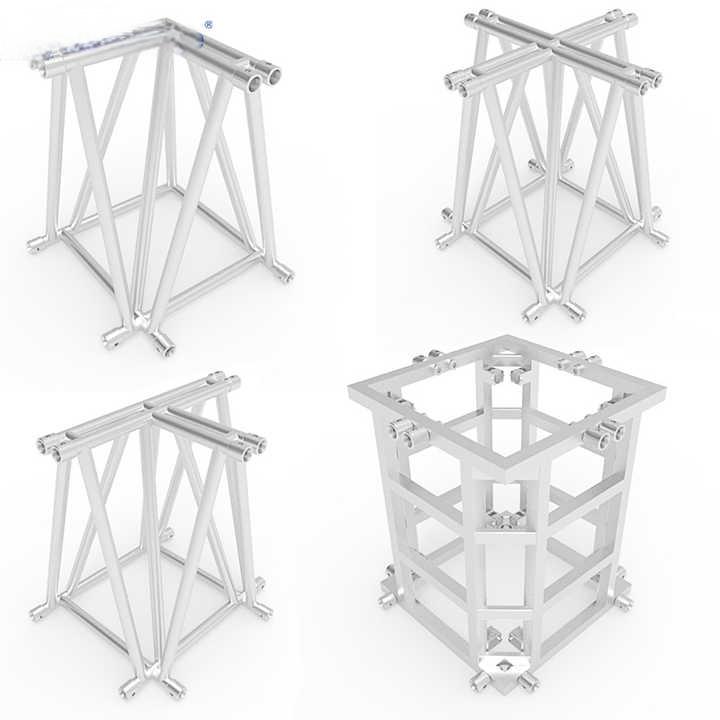

The folding mechanism, an integral part of the system's design, enhances its portability. This is typically achieved through a series of hinges or joints strategically incorporated into the truss's framework, allowing the structure to collapse into a compact configuration for easy transport and storage. These hinges are often designed with robust locking mechanisms to ensure the truss remains stable and secure when deployed. The folding design reduces storage space requirements and simplifies transportation, a crucial advantage in events and applications where mobility is paramount.

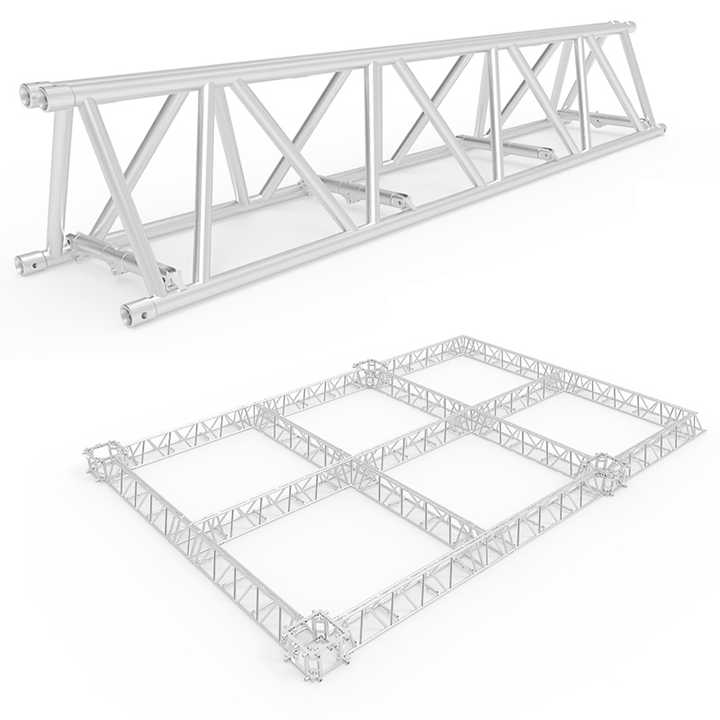

Construction of a spigot aluminum tubular folding truss system involves a relatively straightforward process. Individual tubes are connected to spigots, ensuring proper alignment and a secure fit. The conical shape of the spigot allows for a self-locking mechanism, providing structural stability without the need for additional securing elements. The system's modularity is a key strength, permitting the creation of diverse configurations, from simple square or rectangular trusses to complex, multi-layered structures. This modularity allows for customization to suit specific requirements, accommodating varying load capacities and spatial dimensions.

The advantages of spigot aluminum tubular folding truss systems are numerous. Their lightweight nature significantly simplifies handling and transportation, reducing labor costs and logistical complexities. The rapid assembly and disassembly significantly minimize setup and teardown time, crucial for time-sensitive events. The inherent strength of the aluminum alloy and the secure connections of the spigot system ensure stability and safety, even under significant load. Furthermore, the modularity and adaptability of the system make it suitable for a wide range of applications, from supporting lighting and sound equipment to creating temporary stages and exhibition stands. The corrosion resistance of the aluminum material also contributes to the system's longevity, reducing maintenance requirements and extending its operational lifespan.

Despite its advantages, the spigot aluminum tubular folding truss system presents some limitations. The friction-fit nature of the spigots, while contributing to ease of assembly, can be susceptible to loosening under repeated use or extreme vibrations. Regular inspection and tightening may be required to maintain structural integrity. The system’s load capacity is limited by the dimensions and material properties of the aluminum tubes, requiring careful consideration of the intended loads during design and selection. Moreover, the relatively high initial cost compared to simpler trussing systems can be a deterrent for some users.

Spigot aluminum tubular folding truss systems find widespread application across diverse sectors. In the entertainment industry, they are indispensable for supporting lighting, sound, and video equipment during concerts, theatrical performances, and corporate events. They are also commonly used in the exhibition and trade show industry to create temporary structures for booths and displays. Construction and architectural applications include temporary scaffolding and support structures. Furthermore, they are utilized in photography and film productions to support lighting rigs and cameras.

Looking towards the future, advancements in material science may lead to the development of even stronger and lighter aluminum alloys, further enhancing the performance of spigot truss systems. Innovative design approaches may also optimize the spigot connectors, improving their resistance to loosening and enhancing overall structural stability. The integration of smart technologies, such as embedded sensors to monitor load and stress, could further enhance safety and operational efficiency.